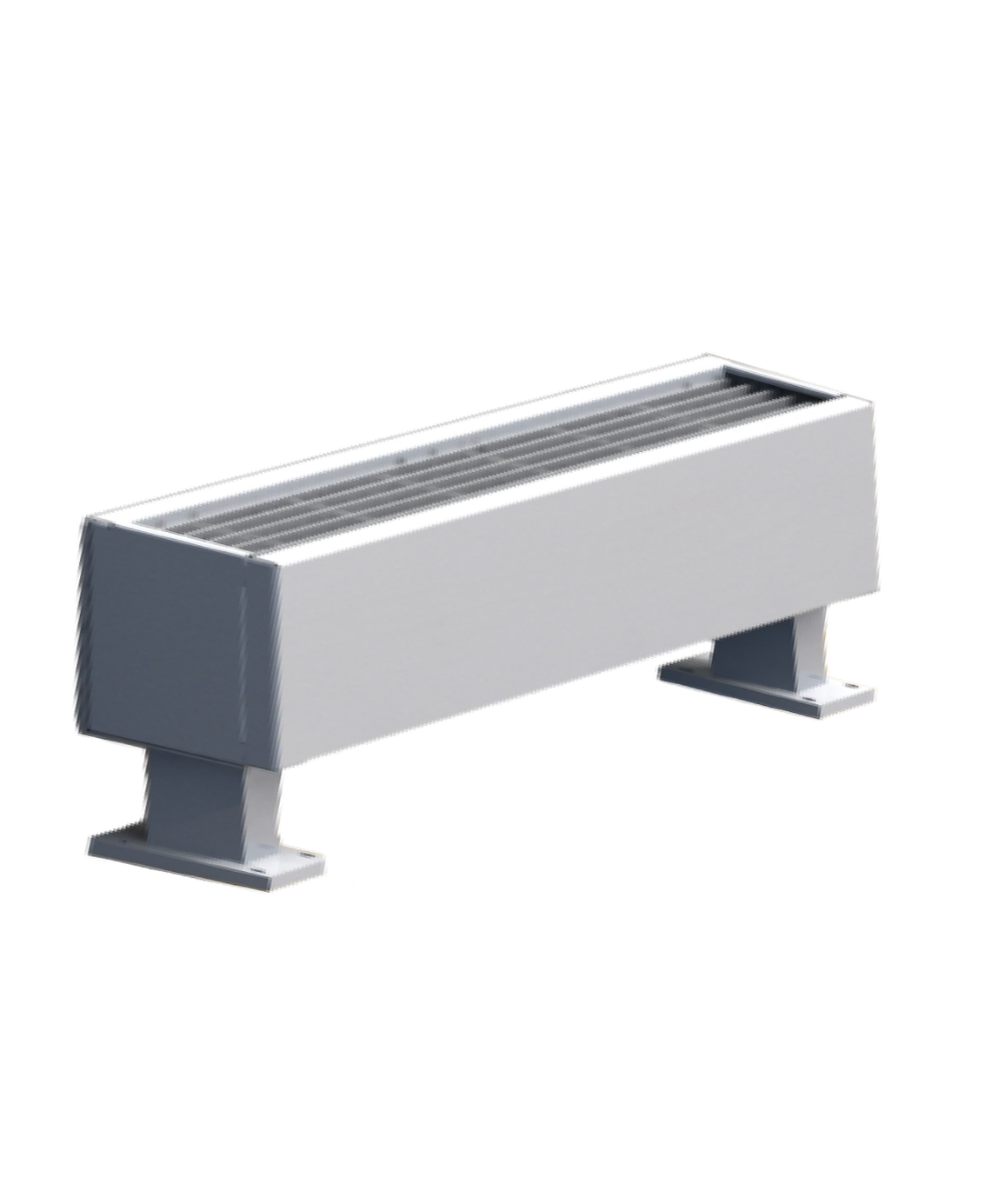

912/913 Commercial Steel High Watt Density Sill-Height Convector

- Ideal for primary, secondary or supplemental heat, under-the-window heat loss and condensation prevention

- Extruded, aluminum grille provides more finished design and appearance

- Durable front cover constructed of 16-gauge steel (optional 14-gauge available)

- Mounting Flexibility: 912 Sill Height (non-pedestal) and 913 pedestal-mounted

- Units may contain 1–3 heating elements that yield a wide range of high watt density heating capacities (see specifications)

- Blend into any décor with 8 standard color options or custom finishes available upon request

- Locate at sill height (or lower) or run from mullion-to-mullion

- Units can be mounted from wall-to-wall or as discrete units in standard lengths of 28 in. to 10 ft.

- Optional built-in controls include: line voltage thermostat (SPST or DPST); power on/off switch; power relay; or transformer relay (see specifications)

- Optional 1/4 in. mesh located under the discharge grille to deter insertion of objects and restriction of airflow

- Right- or left-hand entry/wiring flexibility with identical pre-wired junction boxes at either end

- End-to-End wire-way provided for ease of wiring; and rated per the NEC conduit size and rating codes. Please consult factory for proper sizing and specifications

- Easy connection of supply wiring from bottom, rear or end, as well as multiple wiring of adjacent heaters from one entry point

Approvals

Standard Features

The 912I series is listed for wall mounted applications, while the 913I series is listed for pedestal mounting and comes standard with pedestal kits for mounting and in-field adjustment.

Heaters shall be low profile (5″ x 7″) and available in lengths from 28 inches through 10 feet.

Enclosures shall be 16-gauge (optional 14-gauge front), furniture quality steel with reinforced, all welded construction; designed to withstand heavy-duty commercial and institutional use.

Enclosures shall be chemically-treated to resist corrosion. Finish shall be mar and temperature-resistant to retain contemporary appearance throughout years of rough use.

For safety, the electric heating bank shall consist of metal sheath heating elements. The elements shall have a copper clad steel sheath for strength and corrosion resistance, and aluminum fins for faster heat transfer.

One, two, or three, low density elements shall be installed side-by-side on the same plane to uniformly warm all incoming air. Elements shall be center-anchored and shall float freely on each end through nylon bushings for quietness.

Discharge louvers shall be an extruded aluminum bar grille and direct heat away from wall and to minimize wall surface temperatures and control dirt streaking. Discharge louvers painted to match the heater finish to ensure a clean, decorative finish.

An optional 1/4-inch mesh screen shall be installed beneath the discharge grille to deter the insertion of foreign objects.

Optional built-in controls shall include single-pole, double-pole, or two-stage thermostats, power on/off switch, transformer relay and power relay. The thermostat shall be capable of controlling multiple units on a pilot duty circuit. (Observe the control limitations indicated.) Thermostat adjustment shall be with a thin-bladed screwdriver through the discharge louvers and shall be considered tamper-resistant.

An automatic reset thermal overheat protector shall run the full-length of the heater and shall turn off heating elements should overheating occur at any point along heating length. Overheat protector shall restore operation automatically when cause of overheating is removed. Heaters shall be designed with a built-in prewired race-way to enable multiple unit wiring from one feeder source.

Pedestal legs come standard on the 913I series units. They shall be architecturally styled and shall be individually adjustable to insure an even, level heater installation.

Back panel shall be one piece heavy gauge painted steel, completely finished, and shall be suitable for mullion-to-mullion mounting in front of a glass curtain wall.

28-inch control sections, finished to match the heating units, shall be available with factory built-in mercury contactors, circuit breakers, control transformer, P.E. switch, or SCR controls. This control section shall also be furnished blank, as an optional accessory, for field installation of controls.

All heaters and electrical accessories shall be labeled by Underwriters’ Laboratories, Inc.

Accessories shall include end caps, blank sections, inside and outside corners, splice plates, and telescoping filler sections. All accessories shall be completely enclosed to enable the installer to pull standard wiring from heater to heater through the accessories.

Application Limitations and Precautions

Hazardous Atmosphere: Because the possibility of a concealed spark can exist from the built-in over-head cutout, heaters should not be used in potentially explosive atmospheres.

Corrosive Atmosphere: The high quality finish and steel internal sheet metal parts will give excellent service under most operating conditions, including coastal salt air and industrial atmospheres. However, the finish is not intended for direct salt spray exposure in marine application or highly corrosive greenhouse, swimming pool, chemical storage or industrial atmospheres.

Cleanliness: Although specifically designed for mounting below window areas, heaters can be installed on plaster, wood paneled, metal, masonry or composition wall surfaces with reasonable expectation of clean wall operation. Should some soiling occur, after a period of years, smooth walls may be cleaned with standard maintenance materials. For deep textured walls, consideration should be given choice of enclosure height and watt per foot capacity—generally, the enclosure with lowest surface temperature will have the least soiling tendency.

Comfort: Optimum room comfort results when heater is mounted just below the window sill, since window cold down draft is eliminated and maximum convection air distribution without stratification is maintained throughout the room. Because of the tendency for warm air to stratify, installing heaters close to the ceiling is not recommended. If it should be necessary, at least 18″ clearance above the air discharge must be maintained. Bottom of heaters are not intended for attractive appearance when mounted above eye level.

Air Throw: Since heaters provide only natural convection air throw, they are not recommended for combating cold outside air blasts through high traffic, main entry ways and vestibules. Heaters will maintain satisfactory comfort conditions in low traffic, side entry ways and vestibules, but for most entry ways, faster response fan driven heaters would be preferred.

Curtains, drapes or blinds should clear the top of the heater by at least six inches. See I for vinyl blinds. Never permit draperies to completely cover the unit.

Furniture should be placed so it does not touch the heater and so it does not completely block the air vents. Allow at least 4″ free space between furniture and the heaters.

Recess mounting: UL labeled for free standing wall surface mounting only. Not recommended for mounting behind built-in book shelves, storage cabinets, window seats, etc.

In institutional applications such as hospitals, nursing homes, child day-care centers and clinics, it is recommended that low-watt density convectors be used to provide optimum comfort at lowest case temperatures.

Due to variations in vinyl compositions and their potential to discolor, the use of stand-off brackets (SO1 or SO2) and/or specifying the lower watt density unit may be required when installing on vinyl wall-coverings or under vinyl window dressings.

Prior to setting specifications, consult factory for installation recommendations.

Applications

- Bedrooms

- Living/Family Room

- Kitchens

- Bathrooms

- Basements

- Offices

- Conference Rooms

- Hallways

- Waiting Rooms