Custom HVAC Duct Heater

Heatrex offers special heaters for use in air handling and air conditioning equipment. A wide range of special construction techniques has been developed to insure proper operation as well as easy installation, either in the OEM’s plant or in the field.

Standard Features

Duct heaters shall be Heatrex

Type KUB Custom Slip-in Open Coil Heater

Type PUB Custom Flanged Open Coil Heater

Type TFKU Custom Slip-in Finned Tubular Heater

Type TFPU Custom Flanged Finned Tubular Heater

Approvals

Heaters and panel boards (if required) shall meet the requirements of the National Electrical Code and shall be listed by Under writers Laboratories for zero clearance to combustible surfaces and for use with heat pumps and air conditioning equipment.

Heating elements shall be open coil, 80% nickel, 20% chromium, Grade A resistance wire. Type C alloys containing iron or other alloys are not acceptable. Coils shall be machine crimped into stainless steel terminals extending at least 1″ into the air stream and all terminal hardware shall be stainless steel. Coils shall be supported by ceramic bushings staked into supporting brackets.

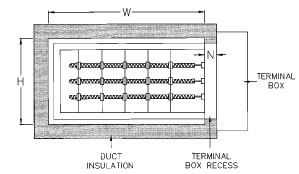

Heater frames and terminal boxes shall be corrosion resistant steel. Unless otherwise indicated, the terminal box shall be NEMA 1 construction and shall be provided with a hinged, latching cover and multiple concentric knockouts for field wiring.

All heaters shall be furnished with a disc type, automatic reset thermal cutout for primary over temperature protection. All heaters shall also be furnished with disc type, load-carrying manual reset thermal cutouts, factory wired in series with heater stages for secondary protection. Heat limiters or other fusible over temperature devices are not acceptable.

Heaters shall be rated for the voltage, phase and number of heating stages indicated in the schedule. All three-phase heaters shall have equal, balanced, three-phase stages. All internal wiring shall be stranded copper with 105°C insulation and shall be terminated in crimped connectors or box lugs.

Terminal blocks shall be provided for all field wiring and shall be sized for installation of 75°C copper wire rated in accordance with NEC requirements.

Heaters shall be furnished either with the Control Option specified in the schedule and described below or with the specific components listed in the schedule.

Product Option

Approvals

Non UL listed

UL listed

Type

KUB (custom slip-in)

PUB (custom flange)

TFKU (custom finned tubular slip-in)

TFPU (custom finned tubular flange)

Control Options

Control G (contactor control)

Control J (pneumatic control)

Control K (SCR control)

Custom Options

“Heater On” pilot light

“Low Airflow” pilot light

Airflow switch for negative pressure operation

Bottom mounted terminal box

Built-in PE transducer

Controls mounted in remote panelboard

Custom terminal box NEMA 12 type

Custom terminal box NEMA 4 type

Custom terminal box UL3R type

Deletion of disconnect switch

Deletion of transformer

Deletion of transformer and contactor

Disconnecting contactors

Dust-tight Terminal Box

Each “Stage On” pilot light(s)

Fan Relay (in addition to Airflow Switch)

Fan relay (instead of airflow switch)

Fuses for heaters rated 48 amps or less

Insulated Terminal Box

Mercury controlling contactors (not available in all areas)

Pilot duty single stage duct thermostat

Pilot duty single stage room thermostat

Pilot duty two stage duct thermostat

Pilot duty two stage room thermostat

Proportional electronic duct thermostat with set point adjuster

Proportional electronic room thermostat

Protective screens

Special inputs (135 ohms, 2200 ohms, 4-20 mA, 0-10 VDC)

Step Controller

Transformer primary fusing