250°F Finned Tubular Heaters

Low temperature heaters, suitable for 250°F maximum outlet air at 900 SFPM minimum airflow, are available in both open coil and finned tubular constructions.

Standard Features

The steel flange is omitted. The heater is attached to the oven or duct wall with sheet metal screws through the base of the terminal box.

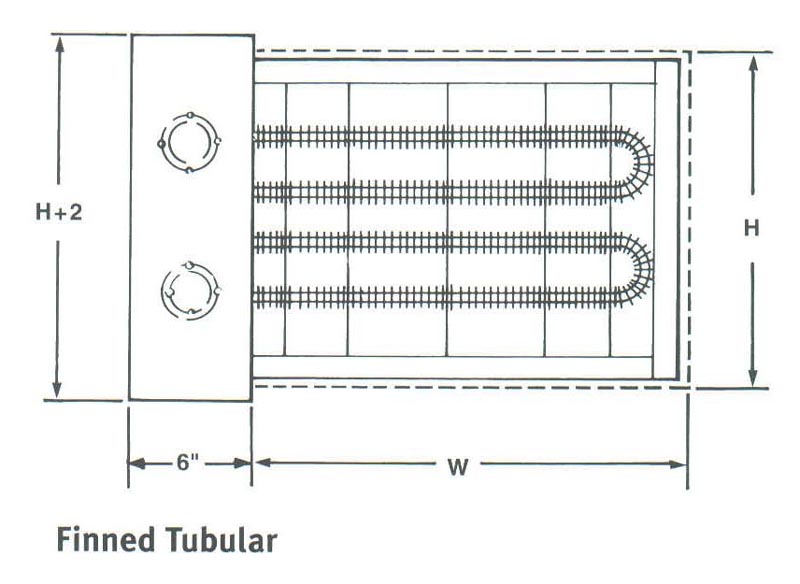

Finned tubular elements are individually field replaceable.

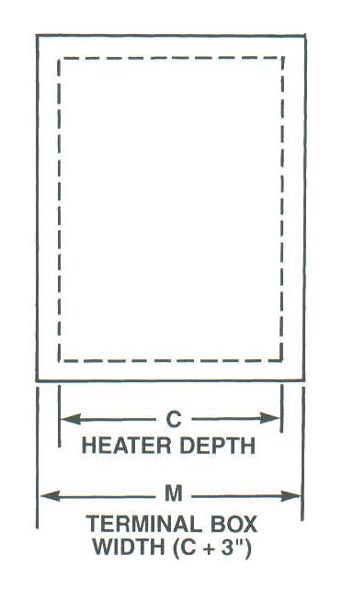

The terminal box has 1″ of insulation.

A galvanized steel channel frame is provided on three sides, with the element support brackets.

ON/OFF process temperature control is recommended for less demanding applications. Systems with two or more heating stages utilize an INDEECO Controls electronic sequencer (step controller), driven by an analog output PID temperature controller to minimize the amount of load cycling while providing good outlet temperature control.

A fully proportional SCR control system with PID temperature control is recommended for industrial heating applications which must accommodate material flow changes and provide the highest degree of accuracy for outlet temperature control.

Applications

Aircraft Manufacturing

Drying

Paint Baking/Drying

Air Curtains

Exhaust Gas Heating

Pharmaceutical

Air Drying

Film Drying

Manufacturing

Annealing

Finishing Systems

Plastic Curing

Booster Heating

Food Processing

Preheating

Baking

Fruit Ripening

Reheating

Batch Heating

Heat Recovery Supplement

Roasting (nut, coffee, corn, etc.)

Chemical Processing

Heat Treating

Semi-Conductor

Cooking

Hopper Heating

Manufacturing

Core Drying

Ink Drying

Sterilizing

Cryogenic Exhaust Gas Heating

Laboratory Testing

Standby Heating

Curing

Make-up Air Heating

Textile Drying

Dehumidification

Metal Finishing

Varnish Drying

Dehydrating

Motor Winding Burnoff

Wire Manufacturing